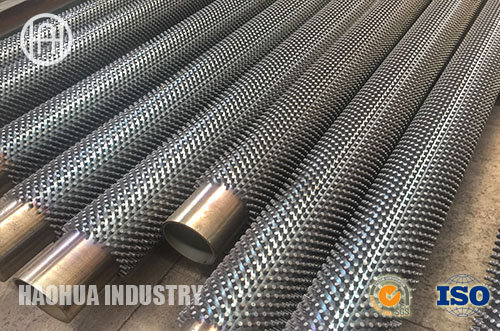

Stud Fin Tubes

Product Categary:

Main Feature:

Jiangsu Haohua Industry Group as one of the leading suppliers in China to supply Stud Fin Tubes etc.[Contact person:Ms Leilei ; Email: Leilei@haopipe.com ]

product description

Stud Fin Tubes

Technical Details

Pipe Details

Pipe Diameter : Min 2” Nb To Max 8” Nb Pipe

Materials : Carbon Steel, Stainless Steel, Duplex & Super Duplex Steel, Alloy Steels (P5,P9,P11, P22), Inconel, High Chrome High Nickle & Incolloy Etc. (any Ferrous Material)

Stud Details

Stud Height : Min 0.5” (12.7 Mm) To Max – 2.5” (63.5MM)

Stud Diameter : Standard Size Is Circular For Extended Portion 0.5” (12.7MM) (can Be Changed As Per Customer Requirement)

Stud Spacing : 0.625” (15.875 Mm) Or 63 Studs Per Plane Per Meter (can Be Changed As Per Customer Requirement)

Stud Materials : Carbon Steel, Stainless Steel And Alloy Steel (Any Ferrous Material)

Specifications

OD 2-20 inch studded tube for boiler

thickness:4-20mm, height:10-38mm

tube:A106GrB, A335 P5/P9,A204 TP304

OD 2-20 inch studded tube for boiler

Studded Tubes are applied to convection chamber of heating furnace in petrochemical industry to increase the heat transfer coefficient at the fuming side. Studded Tubes are two or three times the square of light Tubes. Due to the usage of studded Tubes, the hot strength can be obtained as the same as radiation in the reasonable design. Studded Tubes manufactured by our company adopt resistance welding method. Welding process is controlled by PLC program. Feeding motor and graduation use servo motor. Studded number can be set via the human-computer interface. The graduation parameter and compensating coefficient can be set according to technical requirements to ensure the quality and precision of products.

Application and Work Principle

1. The equipment is used exclusively for the welding of studded tubes. The studded tubes produced using this equipment is an energy-efficient heat exchange component. It is characterized by high heat transfer efficiency and high bearing pressure, and best adapted to high temperature areas. It is mainly used in waste heat recovery, petrochemical, heat exchange systems of power station boilers and other industries.

The application of studded tubes in heating furnace convection chamber of petrochemical industry can increase smoke side heat transfer coefficient. The area of studded tubes is 2 to 3 times that of light tubes. Under the condition of reasonable design, using studded tubes can obtain the same heat intensity as radiation.

2. Studded tube is an integrated heat exchange part processed using power frequency contact type resistance welding and upsetting force fusion welding.

3. The equipment adopts dual-torch metal tumor-free welding. Stepper motor is used for stud head division; and linear guide uses machine head slide. Welding precision is ensured.

4. The studded tubes welder is a mechanical-electrical integrated welder. The electric control part adopts PLC program control and man-machine interface parameter setting, and the operation is simple and reliable. The welding parameters adopt single board computer settings. Its performance is stable and convenient.

Main Technical Parameters

1. Rated input capacity: 90KVA

2. Rated input voltage: 380V±10%

3. Diameter of welded steel tubes: 60-220mm

4. Diameter of welded studs6-14mm (and other abnormally shaped studs)

5. Effective length of welded steel tubes: 13m

6.Axial spacing of welded studs: can be freely adjusted

7. Arrangement of radially welded studs: even number

8. While welding stainless steel materials, preheater is required (made by user self).

- Preview:Studded Pipes

- Next: ASTM A106GrB Fired Heater Tubes